PhDSupervision:Dhananjay Ipparthi

Personal Information

Name: Dhananjay Ipparthi

Date of arrival in Brussels: 08th February, 2012

Home address: Rue des Vierges 58, 1000 Bruxelles

Telephone number: +32 483 382 207

Milestones

- Ring assemble demo in Paderborn, 20th August 2013

- Decision of continuation of fellowship, 31st January, 2014

Academic Activities

6th - 10th January, 2014

Plan

- Finalise procurement

- Screws [waiting confirmation]

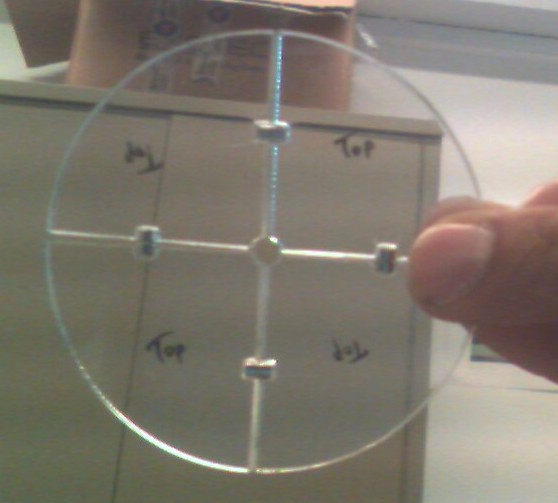

- Cut out acrylic

- Established tolerances for 0.5mm plexiglass - 0,34mm cumulative.

- Finalise test environments

- Follow up with Haitham about 3D printed parts [in progress]

Accomplishments

Others

- Back up option for screws [1]

Todos

- Camera, lights, lens

- Measure universal platform

- Laser cut bracket to check if dimensions are correct

16th - 20th December, 2013

Plan

- Finalise procurement

- Screws [waiting confirmation]

- Cut out acrylic

- Finalise test environments

- Meet Thomas to refine experiment hypothesis [done]

Accomplishments

Others

Todos

- Camera, lights, lens

- Measure universal platform

- Laser cut bracket to check if dimensions are correct

9th - 13th December, 2013

Plan

- Finalise procurement

- Acrylic [paid]

- Screws [waiting confirmation]

- Cut out acrylic

- Design test environments

- Design lid options

- Refine experiment hypothesis

Accomplishments

Others

Todos

- Camera, lights, lens

- Measure universal platform

- Laser cut bracket to check if dimensions are correct

2nd - 6th December, 2013

Plan

- Submit first working design to DMRC

- Follow up orders for screws and acrylic [in progress]

- Submit receipts to Jutta

- Print out previous trip spreadsheet for personal records

- Plan experiments

Accomplishments

Others

Todos

- Camera, lights, lens

- Digital weighing scale [2]

- Measure universal platform

- Laser cut bracket to check if dimensions are correct

25th - 29th November, 2013

Plan

- Tally accounts

- Submit receipts to Jutta

- Print out previous trip spreadsheet for personal records

- Measure universal platform

- Laser cut bracket to check if dimensions are correct

- Spacing of holes

- Holes

- Length, breadth and width

- Pick up components from DMRC [done]

- Experiments with other magnets (N52) and Bismut

* Follow up orders for screws and acrylic

Accomplishments

Others

Todos

- Camera, lights, lens

- Digital weighing scale

18th - 22nd November, 2013

Plan

- Submit designs for printing: [done]

- L-drop component and key

- Straight drop component and key

- Test block to try different components

- Enquire about screws and acrylic sheet

- Update SVN

- Purchase

- Screws

- Acrylic

- Bismut [done]

Accomplishments

Others

Todos

11th - 15th November, 2013

Plan

- Pick up new components from DMRC

- Test new components

- Which magnets to use? --> 3mm side cube, 5mm side cube

- What size of components? --> 50mm radius, 25mm height (earlier 35mm) (done)

- What size of keys? --> Increase dimensions of shaft, change shaft shape (incline to L) (done), keep wall thickness 1.5 (reduce to 1?)

- What gaps between magnet and ferromagnetic material?

- --> For attraction the gap should ideally be a maximum 2mm. This means that since there is a 0.5mm air gap between the key and the magnet, the wall thickness should ideally be 1mm.

- --> To ensure there is no attraction between the ferromagnetic material and the magnet (> 3mm side cube) the separation should be at least 15mm

- Which ferromagnetic material? --> screw

- Redesign components based on test results [ref above]

- Gaps magnet and ferromagnetic magnetic material

- Hole sizes for screw (hole on face) [done]

- Height of component [done]

- Redesign components to make them Radius 25 and Height 15

- Design tube for the magnet to slide in

- Design component such that the face ends with acrylic sheet

- Bismuth beads

Accomplishments

Others

Todos

21st October - 25th October, 2013

Plan

- Submit revised multi-target component design v2

- Conduct experiments with ferromagentic materials

Accomplishments

- Submitted lock-key based design for 3D printing

- Conducted experiments with ferromagnetic material and magnets.

Others

Todos

- Conduct further tests with ferromagnetic materials

- Use different magnets

- Tabulate distance of attraction and magnet strength (and shape?).

- Order magnets

- Make list of parameters that can be adjusted in revised multi-target component design

- Make a list of anticipated errors

- Design refinements to v2 design

- Lip

- Test blocks for angles

15th October - 18th October, 2013

Plan for Paderborn

- Design v2 of multi-target self-assembly system

- Design test blocks to test different parameters

Accomplishments

- Designed v2

- Designed test blocks for:

- Different box sizes for the key

- Different key shapes based on area of attraction

Others

Todos

- Conduct tests on magnets

- Design refinements

- Make list of anticipated errors

07th October - 11th October, 2013

Plan

Accomplishments

Others

Todos

30th September - 04th October, 2013

Plan

- Random shaker design

- Coupling of saw and shaker

- Test on Laser Cutter

- New 3D printer research

Accomplishments

- Requested quote for random shaker

- Requested quote for basic 2D robot

- Submitted revised component design to DMRC

Others

Todos

22nd - 26th September, 2013

Plan

- Shaker choice

- Update expenditures

Accomplishments

- Revised component design

- No unwanted features

- Read paper and highlight important design attributes

- Visted Chem and Physics lab

Others

Todos

16th - 20th September, 2013

Plan

- Submit revised design for 3D printing

- Literature review

- Works citing Hosokawa (1996)

Accomplishments

Others

- 17th September - Received reply from Dr. Hosokawa along with his last work on the self-assembly of multiple structures (1996).

Todos

9th - 13th September, 2013

Plan

- Make corrections to the angle test block design based on feedback from Polyjet Printing services [ongoing]

- Search for shakers [Fisher Scientific, Eppendorf and New Brunswick]

- Weight the shaker is able support atleast 500g of weight

- 220V Euro plug

- Metric holes

Accomplishments

- Compiled a list of shakers

- Marco sent Xeed an email requesting a status update.

Others

Todos

2nd - 6th September, 2013

Plan

- Send Kazuo Hosokawa email regarding paper [done]

- Shaker research [ongoing]

Accomplishments

Others

Todos

- Followup on 3D printer

26th - 30th August, 2013

Plan

- Design components for 3D printing

- Laser sintering

- Test component to test different sliding angles

- Test component to test different magnet separation distances

- Seed component

- Switchable component

- Laser sintering

- Polyjet

- Test component to test different sliding angles

- Test component to test different magnet separation distances

- Polyjet

Accomplishments

- Designs submitted

Others

Todos

19th - 23rd August, 2013

Plan for Paderborn

- Conduct tests on:

- Induced error tests: N-N bond etc

- Complete incomplete experiments

- Buy M3 3cm length screws

- Bracket

- Further search for a random shaker

- Find state of the art for multiple structure assembly [in process]

Accomplishments

Others

- Placed order for magnets

- Magnets are with ULB courier services

Todos

- Make a list of errors for circle shapes

12th - 16th August, 2013

Plan

- Find a shaker that shakes in a random fashion [found one possibility]

- Find state of the art for multiple structure assembly [in process]

- Read Hosokawa paper [done]

- Refinements to existing designs

- Wall thickness [pending]

- Depth of magnets [run tests in Paderborn]

- Maximum and minimum structure sizes [cut 15mm and 25mm acrylic components]

- Update lab journal

- Prepare and pack for Paderborn trip 20130819-23

Accomplishments

Others

- Placed order for magnets

- Magnets are with ULB courier services

Todos

- Make a list of errors for circle shapes

5th - 9th August, 2013

Plan

- Reorganise experiment data from Paderborn visit

- Plot compatibility curve [done]

- Read Hosokawa paper [PENDING]

- Refinements to existing designs [in progress]

- Wall thickness

- Depth of magnets

- Maximum and minumum structure sizes

- Submit expenses for reimbursement [done]

- Marco transferred 800Euro to my bank account on 9th August, 2013

Accomplishments

- Followed up with LaserScript - no response

Others

- Purchased external hard drive to store videos

Todos

- Find a shaker that shakes in a random fashion

- Find state of the art for multiple structure assembly

- Read Hosokawa paper [PENDING]

29th July - 2nd August, 2013

Plan

- Conduct single target experiments on laser cut and 3D printed components in ABS plastic IR94 container

- Conduct multiple target experiments on 3D printed and laser cut components

- Take measurements for new bracket

Accomplishments

- Conducted single target experiments with laser cut components in ABS plastic IR94 container

- 45deg segments IR25OR35

- 90deg segments OR35 circle

- 90deg segments IR15OR25

- 90deg segments IR25OR35

- Conducted single target experiments with laser cut components in acrylic IR75 container

- 45deg segments IR25OR35

- 90deg segments IR25OR35

- 90deg segments OR35 circle

- Conducted single target experiments with 3D printed components in ABS plastic IR94 container

- 45deg segments IR02OR35

- 90deg segments IR25OR35

- Conducted single target experiments with 3D printed components in acrylic IR75 container

- Conducted multiple target experiments with laser cut components in ABS plastic IR94 container

- 90deg segments IR25OR35 x2

- 90deg segments IR15OR25 x2

- 90deg segments IR15OR25 x3

- Conducted multiple target experiments with laser cut components in acrylic IR75 container

- 90deg segments OR35 circle x2

- 90deg segments IR15OR25 x3

- Conducted multiple target experiments with 3D printed components in ABS plastic IR94 container

- 45deg segments IR02OR25 x2

- 45deg segments IR02OR35 x2

- 90deg segments IR25OR35 x2

- Conducted multiple target experiments with 3D printed components in acrylic IR75 container

- 45deg segments IR02OR25 x4

Others

Todos

- Go through JICBackup_videos on kelvin workstation

22nd - 26th July, 2013

Plan

- Conduct tests on N-N error reduction designs

- Cut IR100mm container

- Bracket revision!

- Send LaserScript feedback email

- Prepare for Paderborn trip

- Make a plan for experiments

- Make a list and pack

Accomplishments

Others

Todos

- Update expenses spreadsheet [done]

- Submit expenses to Muriel [done]

15th - 19th July, 2013

Plan

- Send LaserScript email [done]

- Update SVN

- Cut IR 100mm container

- Bracket!

- Find ways to reduce N-N errors [in progress]

Accomplishments

- The laser cutter was previously not calibrated accurately and caused errors in cuts. The cutter is now better calibrated.

- Purchased 5mm plexi-glass sheet, 3 wood beams and Brico Discount Card [€195,47]

- Designed and cut three modifications to reduce N-N error

- Curved edge

- Flanged edge

- Filleted edges

Others

Todos

8th - 12th July, 2013

Plan

- Send bracket sizes to Navneet [Done, €14,59]

- Update Experiments spreadsheet [done]

- Include dimensions of Big and Small environments [done]

- Deeper cuts [done]

- Inclined holes [done]

Accomplishments

- Found suitable air-gap for components

- Found configurations for components with inclined holes to bond

- v-shape

- straight line (causes the pieces to be offset)

Others

- Meeting with Mauro:

- Purchasing acrylic in bulk

- Laser cutter calibration

To dos

- Send LaserScript email regarding errors in calibration

- Deal with bracket fit

1st - 5th July, 2013

Plan

- Paderborn visit (3rd - 5th July, 2013)

- Pack

- Cameras, chargers, cables, memory cards and tripod

- Data storage

- Design notebook, theses, papers

- Magnets

- Glue, tape

- Bracket, environments, lids

- Wing nuts, hex nuts, screws, bolts

- Measuring instruments: vernier, rulers etc.

- Tests

- Assemble components

- Run single ring, two ring, extra pieces tests

- Shaker details

- Pack

Accomplishments

- Hand held experiments at IRIDIA

- Captured videos of single ring and multiple ring assembly experiments. Tabulated the results.

- Conducted tests with extra pieces. The extra pieces used were were:

- Quarter circle

- Full circle

- Shaker experiments in Paderborn

- Speed tests

- Acrylic environment: acrylic components and ABS plastic components

- ABS plastic environment: acrylic components and ABS plastic components

- Tabulated results

- Assembly tests

- Big acrylic environment: 90deg ring segments, 45deg ring segments, 90deg circle segments

- Small acrylic environment: 90deg ring segments, 45deg ring segments, 90deg circle segments

- Tabulated results

- Captured videos

- Speed tests

To do

- Send bracket sizes to Navneet

- Update Experiments spreadsheet

- Include dimensions of Big and Small environments

- Deeper cuts

- Inclined holes

Others

24th - 28th June, 2013

Plan

- Purchased [done]:

- Washer/spacer for M7 and M8 screws - 1 each

- 2m x 1m x 3mm Acrylic sheet - 1

- 6mm Clips - 1

- TOTAL : 111,97 Euro

- Fabricate rings with lesser width [done]

- Test to see if two rings can form simultaneously [done]

- Prepare files and equipment for transport to Paderborn

Accomplishments

- Self assembly of:

- Circle: IR 2mm OR 35mm

- 1 ring: 90deg segments IR 20mm OR 35mm

- 1 ring: 45deg segments IR 20mm OR 35mm

- 2 rings: 90deg segments IR 20mm OR 35mm

- 3 rings: 90deg segments and 45deg segments

Others

17th - 21st June, 2013

Plan

- Purchase acrylic sheets, MDF boards, sand-paper, glue [done] €184,46

- Design and fabricate container for testing in July [done v2, shelved v1]

- Design coupling that will allow any container to be easily mounted onto the shaker. [done v2, shelved v1]

- Update Design Journal and Technical Report.

- Design rings with lesser width

- Observe lateral bonding

Accomplishments

- Developed first self-assembling structure.

- Estimated cutting errors for the Laser Cutter [done]

- Included the design considerations needed to be taken into account because of the errors on the Laser cutter wiki [done]

- Details of the error testing File:LaserCutter Tests.pdf

- Purchased I-section nd L-section channels which will be used as the coupling that will join the container and the shaker. €7,59

- Purchased nuts, bolts and washers. €8,77

- Fabricated and assembled container(s) and brackets

- Containers: IR 75mm and IR 135mm

- Bracket

Other

10th - 14th June, 2013

Plan

- Submit designs for fabrication [done]

- Ensure pieces mate before submission [done]

- Update reports and address Navneet's comments

- Reorganised files and directories [done]

- Revised time lines to reflect 2 week turn around time for 3D printing [done]

- Create entries for 20130607 [done]

- Update Design journal

- Design and fabricate lid [done]

- Design revision

- Assembly simulations in SolidWorks [done]

Other

- Procured 2 suitable glues for acrylics

- Procured magnets

- Test finishing with the 2 glues

- Cut arcs with acrylic

3rd - 7th June, 2013

Plan

- RAR defense [done]

- Set up SVN [done]

- Create two docs: Lab report and detailed report and include them in SVN [done]

- Update Lab report based on meeting with Navneet [done]

- Understood basics of SolidWorks [done]

Other

- Semi ring designed in SolidWorks

1st March, 2013

Literature Review

Project Work

- Work on FRS-FNRS Fellowship application

- Work on Self-Reproduction Review Paper

- Talk in Dubai

Development

Laboratory Activities

- Assisting in big-arena robot storage setup

Ideas

Deliverable

- Synthetic Reproduction Review Paper due by May 2013

- Defense of Report of Advancement on 17th May 2013